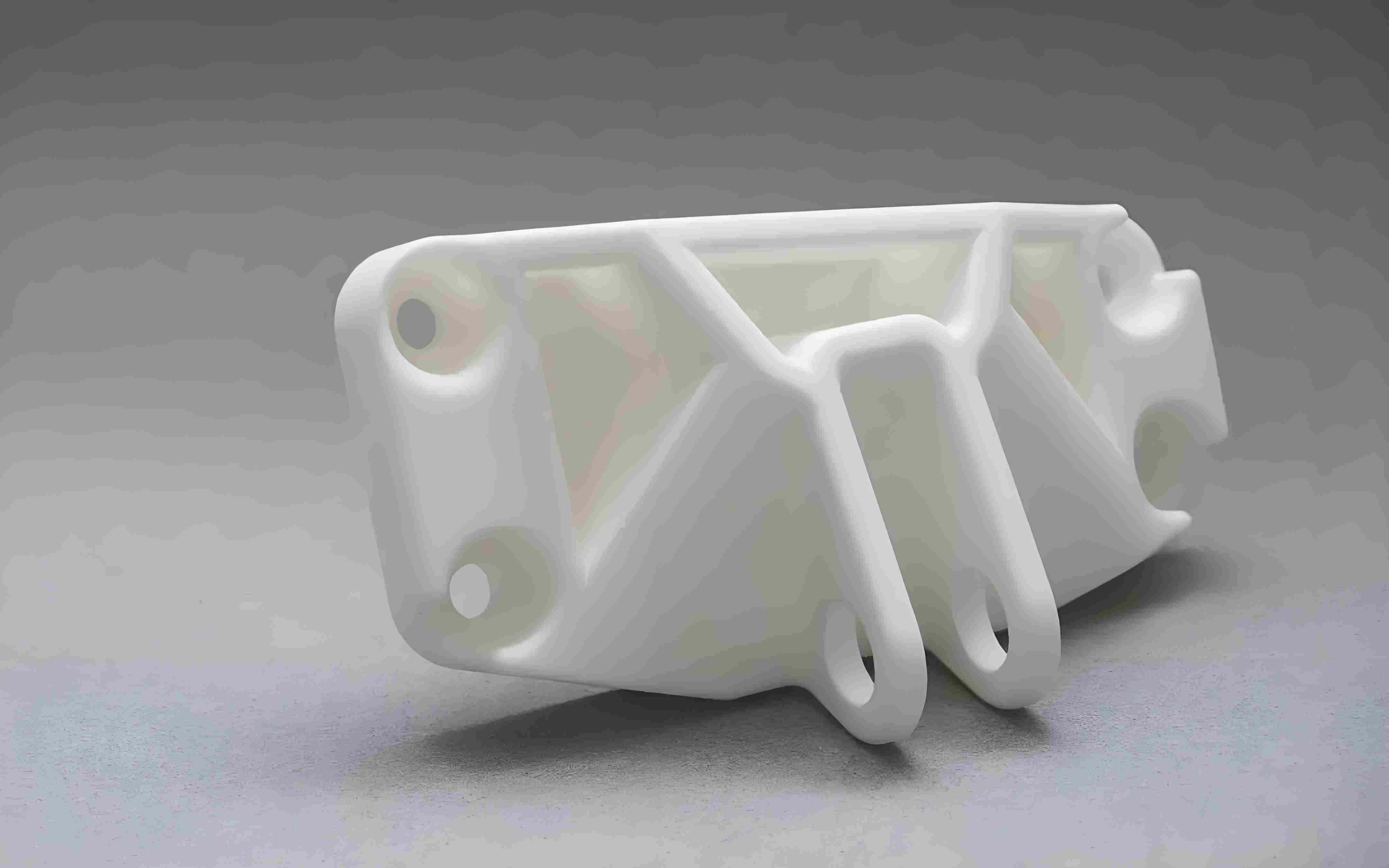

3D printing is an additive manufacturing process where a three-dimensional object is crafted layer by layer, following a digital model. No longer confined to prototyping or simple designs, modern 3D printers can produce complex geometries and employ a range of materials from plastics to metals. At Linkwork, we specialize in high-quality plastics for 3D printing parts, ensuring that our products meet the diverse needs of various industries. Choosing the right materials for your 3D prints is crucial for achieving desired performance and durability. Here’s a guide to help you make informed decisions.

1. Understand Your Project Requirements

Before selecting a material, it’s essential to assess the specific requirements of your project. Consider factors such as:

- Mechanical Properties: Determine whether you need strength, flexibility, or rigidity.

- Thermal Resistance: Assess if the printed part will be exposed to high temperatures.

- Chemical Resistance: Identify any chemicals the part may come into contact with.

Understanding these requirements will guide you toward the most suitable materials.

2. Explore Common 3D Printing Materials

Familiarize yourself with the most common materials used in 3D printing:

- PLA (Polylactic Acid): A biodegradable plastic that is easy to print with and ideal for beginners. It has good surface finish but lower heat resistance.

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength and durability, ABS is widely used for functional parts but requires a heated bed to prevent warping.

- PETG (Polyethylene Terephthalate Glycol): Combines ease of printing with good strength and durability, making it suitable for a variety of applications.

- Nylon (PA): Offers excellent strength and flexibility, making it ideal for functional parts that require durability and wear resistance.

- TPU (Thermoplastic Polyurethane): A flexible material that is great for producing rubber-like parts.

At Linkwork, we provide a range of these materials tailored to meet specific application needs.

3. Consider Advanced Materials

For specialized applications, consider advanced materials such as:

- Carbon Fiber Reinforced Filaments: These materials offer enhanced strength and stiffness while maintaining lightweight properties.

- Metal Filaments: Used for creating parts that require metal-like properties; these typically require more advanced printing equipment.

- Composite Materials: Combining different materials can yield unique properties tailored to specific applications.

4. Evaluate Printing Process Compatibility

Different 3D printing technologies are compatible with specific materials. For example:

- FDM (Fused Deposition Modeling): Works well with thermoplastics like PLA, ABS, and PETG.

- SLA (Stereolithography): Utilizes photopolymer resins that cure under UV light, offering high detail but limited material options compared to FDM.

- SLS (Selective Laser Sintering): Suitable for nylon and other powdered materials, allowing for complex geometries without support structures.

Ensure that the material you choose aligns with your chosen printing technology.

5. Assess Cost and Availability

Material costs can vary significantly based on type and quality. Assess your budget while considering the availability of materials in your region. At Linkwork, we offer competitive pricing on high-quality plastics suitable for various applications.

6. Test Different Materials

If possible, conduct test prints using different materials to evaluate their performance in real-world conditions. This hands-on approach allows you to assess factors such as print quality, strength, and durability before committing to larger production runs.

Conclusion

Choosing the right materials for your 3D prints is essential for achieving optimal results in terms of performance and functionality. By understanding your project requirements, exploring common and advanced materials, considering printing process compatibility, evaluating costs, and testing different options, you can make informed decisions that enhance your 3D printing experience. At Linkwork, we are committed to providing high-quality plastics for all your 3D printing needs. If you have any questions or need assistance selecting the right material for your project, feel free to reach out!