High-density polyethylene (HDPE) sheets, a product born from the polymerization of ethylene, represent a cornerstone of modern manufacturing and construction. Their widespread adoption stems from a unique blend of properties: remarkable strength, chemical resistance, and formability. Unlike many other thermoplastics, HDPE maintains its structural integrity across a broad temperature range, making it suitable for both indoor and outdoor applications. The material's inherent resistance to moisture, acids, and alkalis ensures longevity, even in harsh environmental conditions. The process of creating these sheets involves extruding molten HDPE plastic sheets exporters in Gujarat resin through rollers, resulting in a consistent, uniform product that can be tailored to specific thickness and size requirements.

The Spectrum of Applications

The versatility of HDPE sheets is truly remarkable. In the construction industry, they serve as robust liners for landfills, ponds, and reservoirs, preventing soil and water contamination. Their use extends to creating temporary barriers, concrete formwork, and even playground equipment, where their impact resistance and non-toxic nature are paramount. In agriculture, HDPE sheets are employed as greenhouse coverings, irrigation liners, and animal containment structures, offering protection and durability. The packaging sector benefits from HDPE’s ability to be thermoformed into containers, pallets, and protective packaging. Furthermore, the chemical processing industry relies on HDPE for tanks, pipes, and vessels due to its exceptional resistance to corrosive substances. The material is also a favourite for marine applications, used to make boat hulls and dock components, as it is resistant to saltwater and marine organisms.

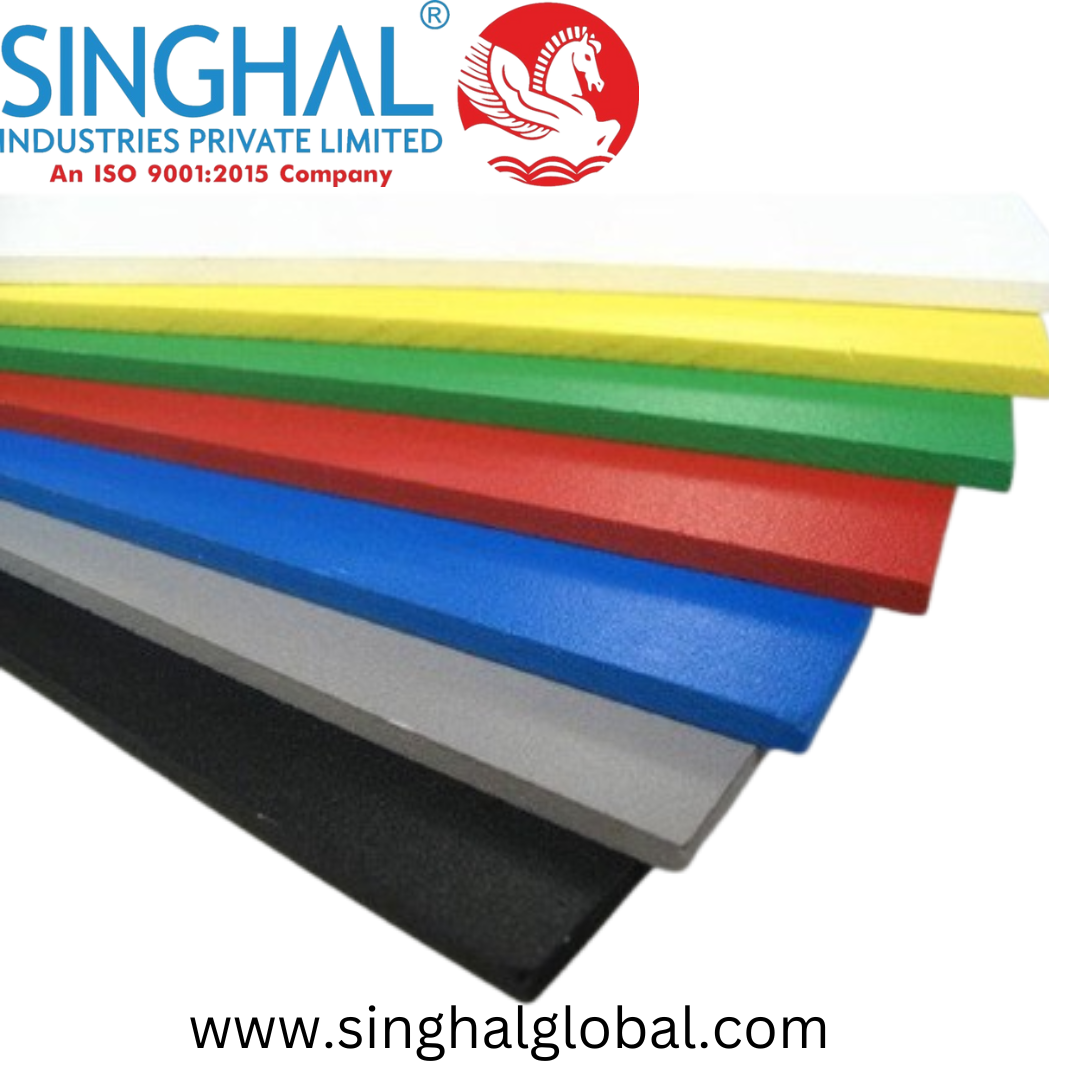

Manufacturing and Customization

The manufacturing process of HDPE sheets allows for a high degree of customization. Sheets can be produced in a wide variety of thicknesses, from thin films to thick, rigid panels, catering to diverse needs. Surface finishes can be varied, from smooth to textured, and colors can be added to match specific aesthetic or functional requirements. The ability to cut, weld, and thermoform HDPE sheets enables fabricators to create intricate shapes and designs, expanding the material’s application possibilities. This flexibility is a significant advantage, allowing for tailored solutions that meet the precise demands of various industries. HDPE plastic sheets exporters in Gujarat play a vital role in providing these customized solutions to a global market, with a focus on quality and precision.

Environmental Considerations

While HDPE is a plastic, it is also highly recyclable. Modern recycling processes can transform used HDPE sheets into new products, reducing waste and conserving resources. This recyclability is crucial in addressing environmental concerns associated with plastic usage. Additionally, HDPE is chemically inert, meaning it does not leach harmful substances into the environment, making it a safer alternative to some other materials. The long lifespan of HDPE products also contributes to sustainability, as it reduces the need for frequent replacements. HDPE polythene sheet suppliers in India are increasingly focusing on sustainable practices, promoting recycling and responsible manufacturing.

Technological Advancements and Future Trends

Ongoing research and development are continuously improving the properties of HDPE sheets. Nanotechnology, for example, is being explored to enhance the material’s strength and durability further. Additives are being developed to improve UV resistance and flame retardancy, expanding the material’s applicability in outdoor and high-temperature environments. The integration of smart technologies, such as sensors embedded within HDPE sheets, is also a growing trend, enabling real-time monitoring of structural integrity and environmental conditions. HDPE products exporters in Ahmedabad are at the forefront of adopting these technological advancements, ensuring that their products remain competitive in the global market.

Economic and Practical Advantages

The cost-effectiveness of HDPE sheets is a significant advantage. Compared to materials like steel or concrete, HDPE is lighter, easier to handle, and requires less maintenance. Its durability and resistance to weathering result in a longer lifespan, reducing replacement costs. The ease of fabrication also translates to lower labor costs, making HDPE a financially viable option for various projects. Furthermore, its lightweight nature reduces transportation costs, making it an attractive choice for large-scale applications. The material’s ability to be welded and joined easily also reduces the need for complex and expensive installation methods.

Conclusion

HDPE sheets stand as a testament to the remarkable versatility and unyielding strength inherent in polyethylene. From safeguarding environmental integrity in landfills to providing durable solutions in agriculture and construction, their applications are diverse and impactful. The ability to customize and adapt these sheets to specific needs, coupled with their cost-effectiveness and environmental considerations, ensures their continued relevance in a rapidly evolving industrial landscape. As technology advances and sustainability becomes increasingly paramount, HDPE products exporters in Ahmedabad will undoubtedly play a crucial role in shaping the future of various sectors.

Frequently Asked Questions

1. What are the key advantages of using HDPE sheets over other materials?

HDPE sheets offer a unique combination of strength, chemical resistance, and formability. They are highly resistant to moisture, acids, and alkalis, ensuring longevity even in harsh environments. Their lightweight nature reduces transportation and handling costs, and they are easily fabricated, welded, and thermoformed, allowing for customized solutions. Additionally, HDPE is recyclable, making it a more environmentally friendly option compared to some other materials.

2. Can HDPE sheets be used for outdoor applications, and how well do they withstand weathering?

Yes, HDPE sheets are well-suited for outdoor applications. They possess excellent resistance to weathering, including UV radiation, moisture, and temperature variations. Additives can be incorporated during manufacturing to further enhance their UV resistance and durability. This makes them ideal for use in applications such as pond liners, greenhouse coverings, and outdoor signage.

3. How does the thickness of an HDPE sheet affect its performance and applications?

The thickness of an HDPE sheet significantly influences its performance and applications. Thicker sheets offer greater strength and rigidity, making them suitable for heavy-duty applications like landfill liners and structural components. Thinner sheets are more flexible and are often used for packaging, protective coverings, and temporary barriers. The choice of thickness depends on the specific requirements of the application, including the load-bearing capacity, flexibility, and environmental conditions.