When it comes to choosing high-performance piping systems for industrial applications, Polyvinylidene Fluoride (PVDF) stands out as a preferred material across many sectors. Known for its superior chemical resistance, thermal stability, and mechanical strength, PVDF pipe fittings are widely used in industries such as chemical processing, water treatment, pharmaceuticals, and oil & gas. As demand for advanced piping solutions continues to rise in the Middle East, identifying the best PVDF pipe fittings manufacturer is crucial for ensuring efficiency, safety, and long-term value.

In this article, we explore what makes PVDF pipe fittings indispensable, the rising demand in the Middle East, and why Petron Thermoplast is considered one of the most trusted manufacturers and suppliers in the region.

Why PVDF Pipe Fittings Are in High Demand?

PVDF is a semi-crystalline thermoplastic fluoropolymer that offers an exceptional balance of properties. Its key advantages include:

- Outstanding chemical resistance: Ideal for handling corrosive fluids in aggressive environments.

- High temperature tolerance: Can withstand continuous use in temperatures up to 150°C.

- Excellent mechanical strength: Withstands pressure and impact even in demanding installations.

- UV and weather resistance: Performs well in outdoor and harsh desert conditions.

- Low permeability and contamination: Suitable for ultra-pure applications, including semiconductor and pharmaceutical industries.

These benefits make PVDF pipe fittings the go-to choice for mission-critical applications, especially in industries where failure is not an option.

Growing Demand in the Middle East Market

The Middle East is witnessing significant industrial expansion, particularly in petrochemicals, desalination, wastewater treatment, and infrastructure development. Countries such as the UAE, Saudi Arabia, Qatar, and Oman are making large-scale investments in upgrading their industrial systems, with a growing emphasis on:

- Corrosion-resistant materials for chemical handling

- Durable piping networks that can withstand extreme temperatures and pressure

- Reliable systems that minimize downtime and maintenance

As industries demand high-purity, long-lasting solutions, the market for PVDF piping systems—especially fittings that form the backbone of any fluid handling system—is seeing a sharp upward trajectory.

Key Qualities of the Best PVDF Pipe Fittings Manufacturer

Selecting a top-tier manufacturer is essential for ensuring performance, safety, and ROI. Here are some essential qualities that define the best PVDF pipe fittings manufacturers:

- Material Quality and Standards Compliance

The best manufacturers use virgin, high-grade PVDF resin to ensure product integrity. Compliance with international standards such as ASTM, DIN, ISO, and NSF is critical.

- Wide Product Range

A reliable supplier offers a complete range of fittings—elbows, tees, reducers, couplers, flanges, and more—to support diverse industrial layouts.

- Customization Capabilities

Industries often have unique requirements. A good manufacturer should offer customized fittings, sizes, and configurations as per project specifications.

- Advanced Manufacturing Infrastructure

Precision engineering, automation, and stringent quality control processes are necessary to produce fittings that meet the demands of harsh industrial environments.

- Strong Distribution Network

Timely delivery is critical for project success. A manufacturer with a strong logistics and distributor network ensures availability even in remote locations.

- After-Sales Support and Technical Assistance

Ongoing support, technical advice, and installation guidance are valuable assets that top manufacturers provide.

Why Petron Thermoplast Leads the Market?

When it comes to high-quality PVDF pipe fittings in the Middle East, Petron Thermoplast stands out as a market leader. With years of expertise in thermoplastic piping systems and a strong reputation for excellence, Petron Thermoplast has become the go-to partner for numerous industrial sectors across the region.

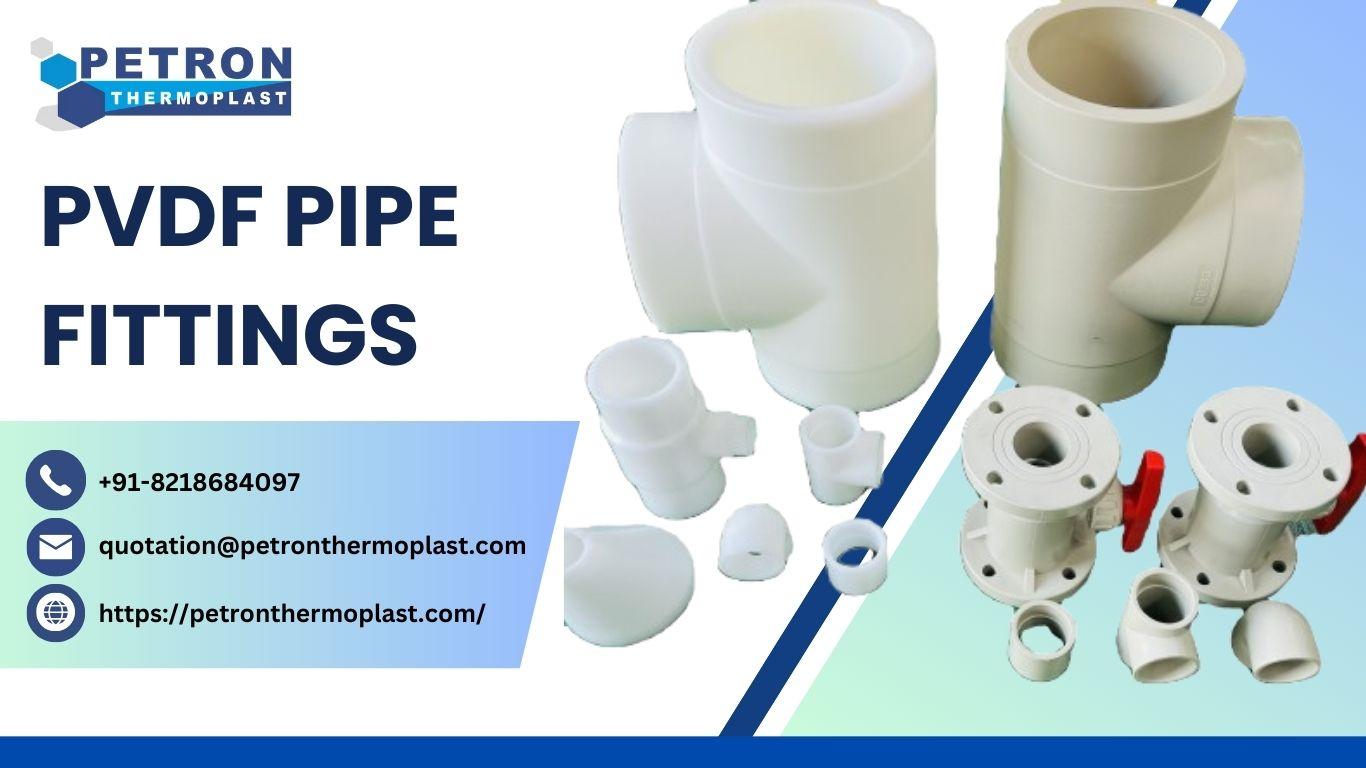

Extensive Product Portfolio

Petron Thermoplast offers a comprehensive range of PVDF pipe fittings, including:

- PVDF Elbows (45°, 90°)

- PVDF Tees (equal and reducing)

- PVDF End Caps

- PVDF Flanges

- PVDF Couplers

- PVDF Reducers

- PVDF Valves and Accessories

Each product is manufactured using high-purity PVDF resin and tested under stringent conditions to meet global quality standards.

Industry-Centric Solutions

From high-purity water systems to corrosive chemical processing applications, Petron Thermoplast caters to a wide array of industries:

- Chemical and Petrochemical Plants

- Desalination and Water Treatment Facilities

- Food and Beverage Processing

- Pharmaceutical Manufacturing

- Semiconductors and Electronics

- Mining and Power Generation

Commitment to Quality

Petron Thermoplast operates with a clear focus on delivering products that exceed client expectations. All PVDF fittings undergo rigorous quality control checks and meet certifications such as ISO 9001, CE, and other industry-specific standards.

Regional Availability and Prompt Delivery

With a robust network of distributors and logistics partners throughout the Middle East, Petron Thermoplast ensures quick and reliable delivery. Whether you’re based in Saudi Arabia, UAE, or Kuwait, your PVDF pipe fittings can be sourced without delays.

Customized Solutions and Technical Support

Petron Thermoplast understands that every project is unique. Their team of engineers and technicians work closely with clients to provide tailored solutions, including:

- Custom molded PVDF components

- Technical support for design and installation

- On-site inspections and project consultations

Future-Ready and Environmentally Responsible

In addition to product performance, Petron Thermoplast also invests in eco-friendly practices and sustainable manufacturing. Their PVDF products are recyclable and manufactured with minimal environmental impact, aligning with the growing need for green industrial solutions.

Conclusion

The demand for PVDF pipe fittings in the Middle East is growing rapidly, fueled by industrial development, stringent safety standards, and the need for high-performance piping systems. In this evolving landscape, selecting the right manufacturer is critical to achieving long-term success.

Petron Thermoplast has emerged as the best PVDF pipe fittings manufacturer and supplier in the region, thanks to its commitment to quality, innovation, and customer-centric solutions. Whether you are building a new facility or upgrading an existing system, Petron Thermoplast provides the reliability, efficiency, and technical support needed to ensure seamless fluid handling in even the most demanding applications.

For bulk orders, customized solutions, or project consultations, connect with Petron Thermoplast—your trusted partner in advanced piping systems.