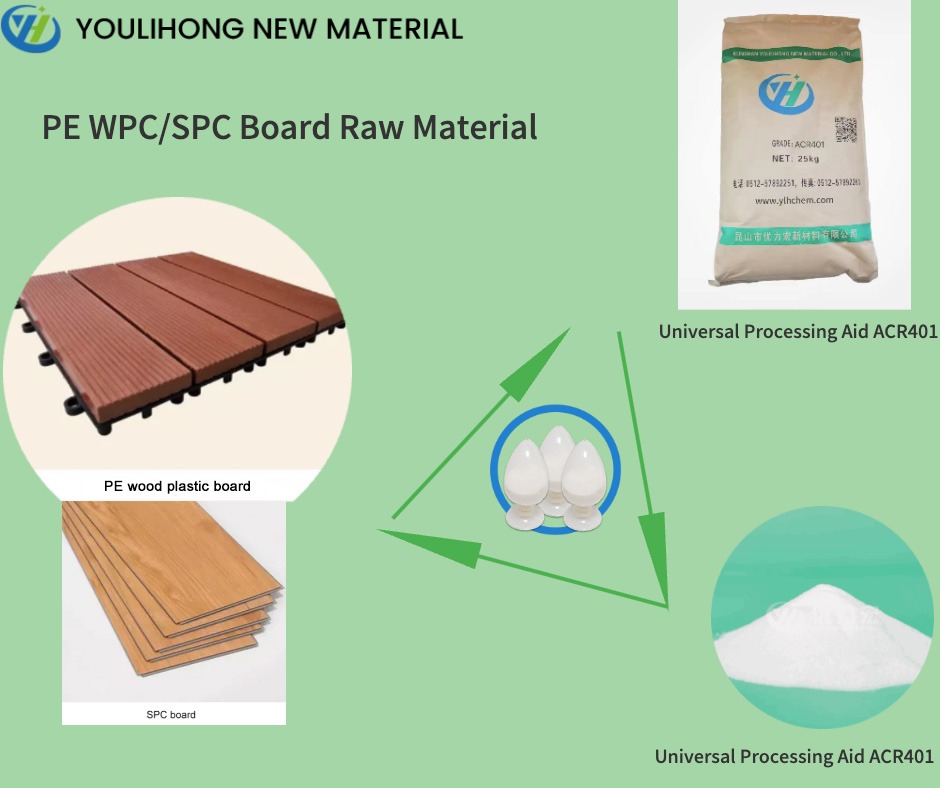

In the manufacturing landscape, achieving high product quality is paramount. One crucial component that significantly contributes to this goal is the Universal Processing Aid. At Youlihong, we offer a specialized Universal Processing Aid designed for various applications, including PE WPC boards and SPC boards. This blog will explore how universal processing aids enhance product quality across different industries.

1. Enhancing Material Flow

Improved Process Efficiency

Universal processing aids, such as our product with CAS No. 25213-88-1, are formulated to improve the flow properties of materials during processing. By enhancing thermofluidity, these aids allow for smoother and faster extrusion processes, which is essential in producing consistent and high-quality products.

2. Reducing Defects

Minimizing Production Issues

Using a universal processing aid helps minimize defects such as bubbles, voids, and inconsistencies in the final product. The aid improves melt strength and elongation, ensuring that materials like PVC and WPC are uniformly processed. This uniformity leads to fewer defects and higher overall product quality.

3. Enhancing Mechanical Properties

Strengthening Final Products

Universal processing aids contribute to the mechanical properties of the end products. By improving the mixing and dispersion of additives within the polymer matrix, these aids enhance tensile strength, flexibility, and durability. For example, when used in SPC floor products or wood-plastic composites, they help achieve robust and long-lasting materials.

4. Facilitating Processing at Lower Temperatures

Energy Efficiency

Another advantage of using universal processing aids is their ability to facilitate processing at lower temperatures. This not only conserves energy but also reduces thermal degradation of sensitive materials. By maintaining the integrity of the raw materials during processing, manufacturers can ensure that the final products meet high-quality standards.

5. Supporting Environmental Compliance

Meeting Regulatory Standards

Many universal processing aids are designed to conform to environmental protection standards, such as those set by the EU. This compliance ensures that manufacturers can produce high-quality products while adhering to regulations regarding safety and environmental impact.

6. Versatility Across Applications

Broad Industry Use

Universal processing aids are versatile and can be applied across various industries, including construction, automotive, electronics, and food packaging. Their ability to improve product quality makes them invaluable in producing a wide range of materials—from SPC flooring to medical devices.

7. Cost-Effectiveness

Maximizing Return on Investment

By improving product quality and reducing defects, universal processing aids can lead to significant cost savings for manufacturers. Higher-quality products result in fewer returns and reworks, ultimately maximizing return on investment (ROI).

Conclusion

The role of universal processing aids in enhancing product quality cannot be overstated. From improving material flow and reducing defects to enhancing mechanical properties and supporting environmental compliance, these aids are essential for manufacturers aiming for excellence in their products.

At Youlihong, our Universal Processing Aid for PE WPC boards and SPC boards is designed to meet your specific needs while ensuring high-quality outcomes in your production processes. If you have any questions about our products or would like to learn more about how they can benefit your operations, feel free to reach out!