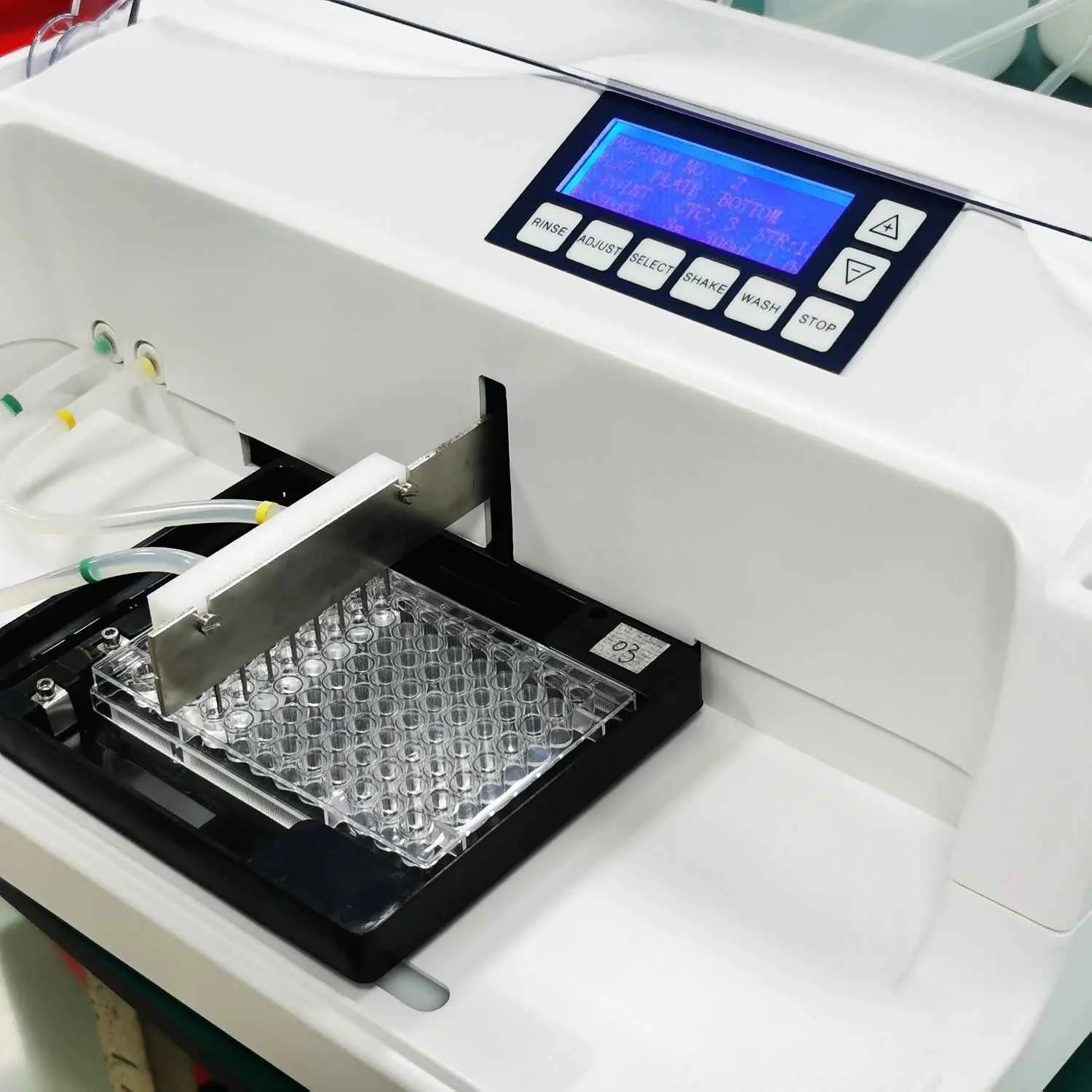

Microplate washers are essential tools in laboratories, particularly for assays like ELISA, where precision and efficiency are paramount. At DIATEK, our Microplate Washer DRW-310 is designed with advanced features such as an 8-button control panel, large LCD display, and the ability to wash both whole plates and individual strips. However, like any piece of laboratory equipment, issues may arise during operation. This blog will guide you through common troubleshooting steps to ensure your microplate washer operates smoothly.

1. Check Power Supply

If your microplate washer does not turn on or respond to commands, the first step is to check the power supply. Ensure that the machine is plugged in securely and that the outlet is functioning. If possible, test the outlet with another device to confirm it has power.

2. Inspect Connections and Cables

Loose or damaged cables can lead to operational issues. Inspect all electrical connections and cables for signs of wear or damage. Ensure that all connections are secure and that there are no exposed wires.

3. Review User Settings

Sometimes, the issue may stem from incorrect settings on the control panel. Review the user settings on your DRW-310, including wash cycles, soak times, and aspiration times. Make sure they are set according to your protocol requirements.

4. Clean the Manifold

If you notice uneven washing or residual liquid in wells after a wash cycle, it may be due to a clogged manifold. Remove the manifold and clean it thoroughly with appropriate cleaning solutions to ensure proper fluid flow.

5. Check for Air Bubbles

Air bubbles trapped in the system can affect washing efficiency. If you suspect this is an issue, try running a wash cycle with a cleaning solution to help dislodge any air bubbles. Ensure that all tubing is properly connected and free of kinks.

6. Monitor Residual Volume

If residual volumes exceed the expected ≤1μL/well after washing, check the aspiration settings and ensure that the aspiration time is sufficient for your specific plate type and liquid volume.

7. Examine Liquid Levels

Ensure that there is enough washing solution in the reservoir. Low liquid levels can lead to inadequate washing performance. Refill the reservoir as needed and check for any leaks in the system.

8. Inspect for Mechanical Issues

If your microplate washer makes unusual noises or if any components seem misaligned, inspect for mechanical issues. Look for signs of wear on moving parts such as pumps or motors, and address any misalignment immediately.

9. Update Software/Firmware

For automated microplate washers, ensure that you have the latest software or firmware updates installed. Outdated software can lead to operational glitches or compatibility issues with newer protocols.

10. Consult the User Manual

When in doubt, refer to the user manual provided by DIATEK for troubleshooting specific error codes or operational problems related to your Microplate Washer DRW-310.

Conclusion

Troubleshooting your microplate washer does not have to be a daunting task. By following these steps—checking power supply and connections, reviewing user settings, cleaning components, monitoring residual volumes, ensuring proper liquid levels, inspecting for mechanical issues, updating software, and consulting the user manual—you can quickly identify and resolve common issues with your equipment. At DIATEK, we are committed to providing high-quality laboratory solutions along with support for maintaining optimal performance in your operations. If you encounter persistent issues or need further assistance, do not hesitate to reach out!