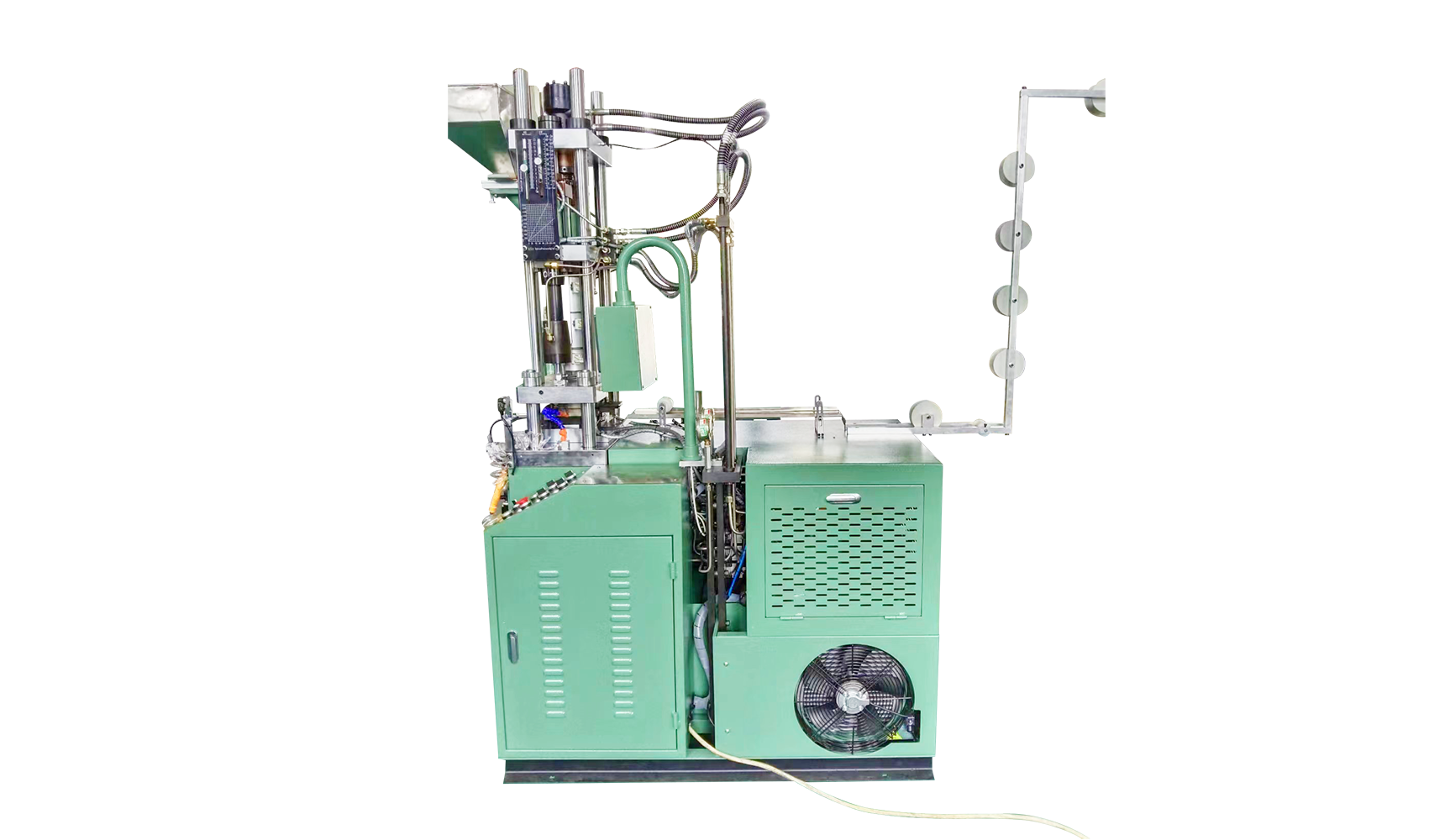

Manufacturers in the textile and accessory industries face constant pressure to increase production speed, reduce costs, and maintain high standards of quality. The Plastic Zipper Machine is a cutting-edge tool that allows businesses to meet these challenges head-on, offering automation and precision that significantly improve the zipper manufacturing process.

The Plastic Zipper Machine is designed to handle large volumes of production, offering enhanced consistency and efficiency. By automating the injection molding process, this machine reduces the need for manual labor, minimizes errors, and accelerates production time, all while maintaining the highest level of quality.

Why Automation Matters in Zipper Manufacturing

In traditional zipper manufacturing, the production process often relied on manual labor for tasks such as molding, assembling, and inspecting zippers. While this method allowed for customization and flexibility, it was prone to inconsistencies, slow speeds, and high labor costs. The Plastic Zipper Machine addresses these issues by automating the molding process, allowing for faster production and uniformity across every zipper.

Using advanced servo-driven technology, the machine ensures precise control over the injection molding process. This means each zipper is formed to exact specifications, resulting in fewer defects and less material waste.

Features of the Plastic Zipper Machine

-

Automatic Injection Molding: The machine uses an automatic injection molding system to produce the zipper components, ensuring high precision and uniformity. This process reduces manual intervention and enhances production efficiency.

-

Servo-Driven Technology: The servo motor system used in the Plastic Zipper Machine ensures precise and consistent results. This system minimizes errors that can occur with traditional methods, improving both product quality and speed.

-

High-Speed Production: With automation in place, the Plastic Zipper Machine is capable of producing zippers at a much faster rate compared to manual methods. This is particularly valuable for manufacturers with high-volume orders or tight deadlines.

-

Energy Efficient: Compared to traditional machines, the Plastic Zipper Machine operates with energy-efficient technology, reducing electricity consumption and lowering overall operational costs.

-

Cost-Effective Solution: Although there is an initial investment in the machine, the long-term savings in labor costs and material wastage make the Plastic Zipper Machine a cost-effective choice for large-scale manufacturers.

Benefits for Manufacturers

- Increased Efficiency: Automation speeds up production, allowing manufacturers to produce more zippers in less time.

- Cost Savings: The reduction in labor and material waste leads to significant cost savings.

- High-Quality Standards: The machine ensures uniformity and precision, reducing defects and improving overall product quality.

- Scalability: The Plastic Zipper Machine can scale with your business, handling larger production volumes as demand increases without requiring significant investment in new equipment.

Conclusion

For businesses looking to improve their zipper production process, the Plastic Zipper Machine is a smart investment. By automating key aspects of production, manufacturers can achieve greater efficiency, reduce costs, and ensure high-quality output. Explore the potential of this cutting-edge machine to streamline your operations by visiting the Plastic Zipper Machine product page.

Article 8: Scaling Zipper Production with the Plastic Zipper Machine

In industries where zippers are essential components, such as fashion, luggage manufacturing, and even automotive, production efficiency and quality control are crucial. To meet these demands, manufacturers need machines that are reliable, versatile, and capable of high-volume output. The Plastic Zipper Machine is designed to do just that, offering an automated solution for faster and more efficient zipper manufacturing.

With advanced servo-driven systems and automatic injection molding, the Plastic Zipper Machine helps streamline production lines while maintaining consistent quality. This article explores why adopting this machine is a game-changer for manufacturers looking to scale operations without compromising on precision.

The Importance of Automation in Zipper Manufacturing

Manual zipper manufacturing processes are often slow, prone to errors, and costly due to high labor demands. With the Plastic Zipper Machine, these challenges are addressed through automation. The machine uses an automatic injection molding system to produce zipper teeth and sliders with great precision. This automation allows manufacturers to produce zippers quickly and with consistent quality, reducing the need for additional workers and minimizing errors.

Moreover, the servo-driven technology allows the machine to operate with precision, ensuring that each zipper is created to exact specifications, resulting in fewer defects and less waste.

Key Features of the Plastic Zipper Machine

-

Automatic Injection Molding: The machine automates the injection molding process, producing the zipper components automatically. This reduces labor costs and improves overall production efficiency.

-

Servo-Driven Control: The Plastic Zipper Machine features a servo motor that ensures precise control over the injection process. This technology enhances the accuracy and consistency of each zipper, reducing the chance of defects.

-

Speed and Scalability: With its automated system, the machine can produce large quantities of zippers in a short amount of time. This is ideal for manufacturers with high-volume orders or those looking to scale their production as demand increases.

-

Energy Efficiency: The machine is designed with energy efficiency in mind, reducing power consumption and lowering the overall cost of operation.

-

Cost Efficiency: Although the initial cost may seem high, the machine’s ability to reduce labor and material waste results in substantial long-term savings.

Why Choose the Plastic Zipper Machine?

For manufacturers seeking to improve their zipper production process, the Plastic Zipper Machine offers several benefits:

- Increased Efficiency: By automating key tasks, the machine accelerates the production process, allowing manufacturers to meet tight deadlines and handle larger orders.

- Cost Savings: Automation reduces labor costs and minimizes waste, leading to greater cost efficiency.

- High-Quality Production: The precise control offered by the servo-driven system ensures that every zipper meets quality standards, reducing defects and ensuring consistency.

- Adaptable: The machine can accommodate different zipper sizes and designs, making it a versatile choice for manufacturers in various industries.