Anti-static table mats play a crucial role in various industries where electrostatic discharge (ESD) poses a risk to sensitive electronic components. These mats are specially designed to dissipate static electricity, thereby preventing damage to electronic devices and ensuring safe working environments.

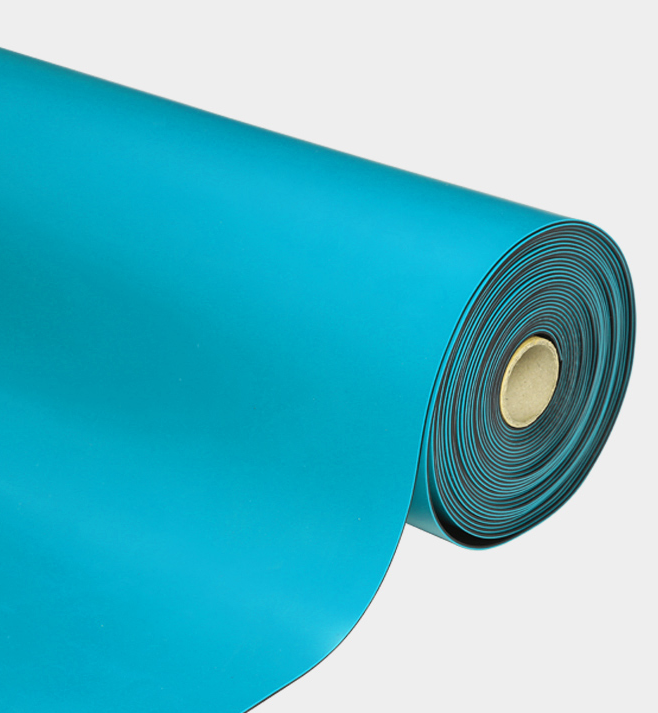

The primary function of an anti-static table mat is to provide a controlled path for static electricity to flow safely to the ground. Typically made from materials with specific electrical properties, such as conductive rubber or vinyl, these mats are placed on work surfaces where electronic assembly, testing, or repair tasks are performed.

In addition to their electrical conductivity, anti-static table mats often feature a textured surface that improves grip and prevents components from sliding during handling. Some mats also include grounding hardware, such as snap fasteners or grounding cords, to ensure effective static dissipation.

Industries that rely on anti-static table mats include electronics manufacturing, telecommunications, aerospace, and healthcare. These mats are essential in environments where even minor static discharges can damage sensitive equipment or compromise product quality.

As technology continues to advance, the demand for reliable ESD protection grows, driving innovation in anti-static materials and mat designs. Manufacturers continually strive to enhance conductivity, durability, and ergonomic features to meet the evolving needs of industry standards and workplace safety regulations.

Overall, anti-static table mats are indispensable tools for maintaining electrostatic control in sensitive electronic environments. Their role in preventing costly damage and ensuring operational reliability underscores their importance across diverse sectors where ESD protection is paramount.