In the intricate world of manufacturing, the Plastic Crate Mould Factory stands as a testament to the importance of product safety. The assurance of safety in the production process is paramount, as it directly impacts the end-users and the reputation of the Plastic Crate Mould Factory. Implementing a comprehensive safety strategy is a multi-layered approach that begins with the design phase and extends through to the distribution of the final product.

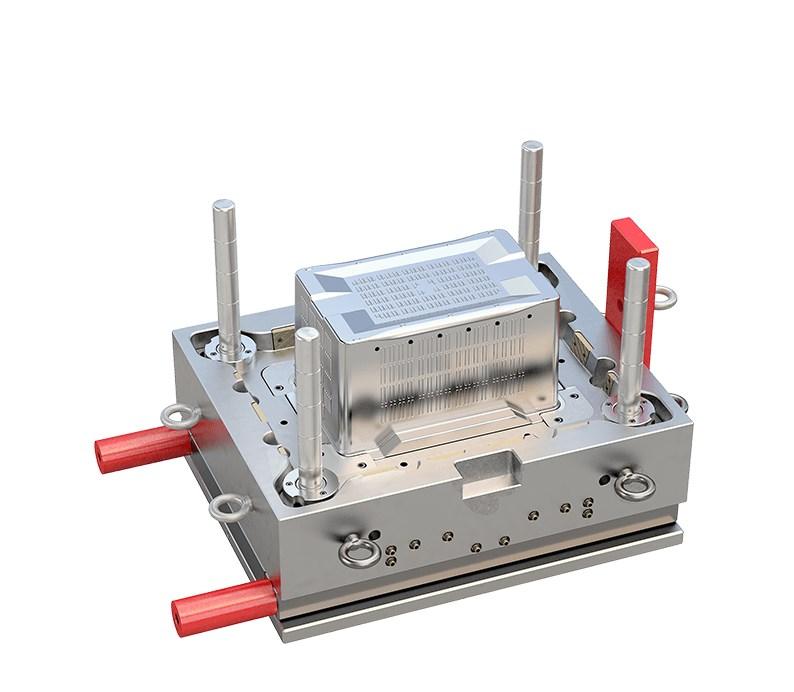

The initial step in ensuring product safety is the meticulous design of the plastic crate molds. The Plastic Crate Mould Factory invests in state-of-the-art design software and employs skilled engineers who are adept at creating molds that meet or exceed industry safety standards. These designs are subjected to rigorous stress tests and simulations to predict their performance under various conditions, thereby minimizing the risk of failure during use.

Once the design is finalized, the Plastic Crate Mould Factory transitions to the manufacturing phase, where the focus shifts to the selection of materials. High-quality, food-grade plastics are chosen to ensure that the crates are not only durable but also safe for use in various industries, including food and pharmaceuticals. The Plastic Crate Mould Factory also maintains strict quality control measures to ensure that the raw materials are free from contaminants.

During the production process, the Plastic Crate Mould Factory employs advanced machinery and automation technologies to reduce the risk of human error. The use of robotics and computer-numerical control (CNC) machines ensures precision and consistency in the manufacturing of each crate. Additionally, the factory implements a series of in-process inspections to identify and rectify any deviations from the set quality standards.

After the crates are manufactured, they undergo a series of stringent tests to evaluate their structural integrity, load-bearing capacity, and resistance to environmental factors such as temperature and humidity. The Plastic Crate Mould Factory also conducts drop tests and stack tests to ensure that the crates can withstand the rigors of transportation and storage.

To further enhance product safety, the Plastic Crate Mould Factory incorporates user-friendly features into the design of the crates. These include ergonomic handles, secure locking mechanisms, and marked weight limits. The factory also provides detailed user manuals and safety guidelines to educate customers on the proper use and handling of the crates.

In addition to these internal measures, the Plastic Crate Mould Factory actively engages with regulatory bodies and industry associations to stay abreast of the latest safety standards and best practices. The factory also encourages customer feedback and is committed to addressing any safety concerns promptly and effectively.

The Plastic Crate Mould Factory also places a strong emphasis on employee safety, recognizing that a safe working environment is essential for maintaining high-quality production standards. The factory provides regular training to its workforce on safety protocols, emergency response procedures, and the proper use of personal protective equipment (PPE).

Furthermore, the Plastic Crate Mould Factory is committed to environmental sustainability, which is an integral part of its safety strategy. The factory employs eco-friendly manufacturing processes and uses recyclable materials to minimize its environmental footprint. This commitment to sustainability not only benefits the environment but also enhances the safety of the products by reducing the risk of exposure to hazardous substances.

In conclusion, the Plastic Crate Mould Factory's dedication to product safety is evident in every aspect of its operations, from the design and manufacturing processes to the testing, employee training, and environmental practices. By maintaining a vigilant focus on safety, the Plastic Crate Mould Factory ensures that its products meet the highest standards of quality and reliability, providing customers with a safe and dependable solution for their storage and transportation needs.