In the realm of industrial materials, conveyor belts play a pivotal role in the efficient transportation of goods across various sectors. Among these, anti-tear conveyor belts stand out for their exceptional strength and durability. Designed to withstand the rigors of heavy-duty applications, these belts are engineered to minimize the risk of撕裂, ensuring continuous operation and reduced downtime.

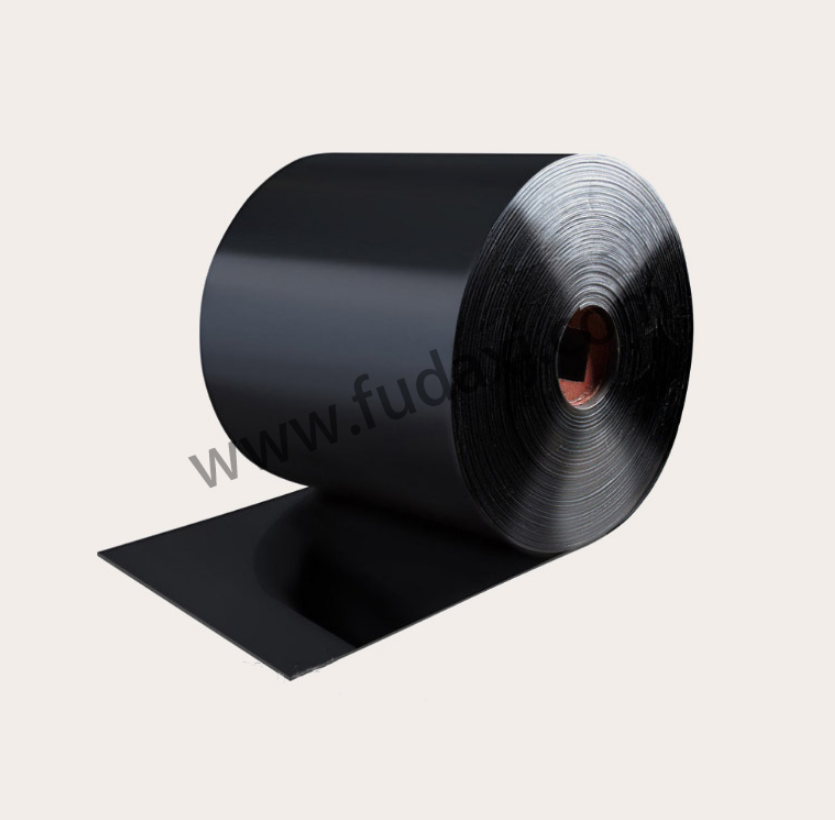

The unique properties of anti-tear conveyor belts lie in their construction. They are made from high-strength synthetic fibers that are woven into a tight, robust fabric. This fabric is then bonded with a layer of rubber to create a belt that is not only resistant to tearing but also offers excellent resistance to abrasion and impact. The result is a belt that can handle sharp, heavy, or abrasive materials without compromising its integrity.

In industries such as mining, construction, and aggregates, where materials like rocks, gravel, and sand are frequently transported, anti-tear conveyor belts are invaluable. They can endure the harsh conditions and maintain performance, even when subjected to repeated stress and strain. This durability translates into cost savings for businesses, as the need for frequent belt replacements is significantly reduced.

In summary, anti-tear conveyor belts are a critical component in industries that require robust and reliable material handling solutions. Their ability to resist tearing and withstand harsh conditions makes them an ideal choice for ensuring the smooth and efficient operation of conveyor systems.