Cart Wheel Chocks are essential safety equipment used to secure vehicles in place, preventing unwanted movement that could lead to accidents or damage. Their performance in various weather conditions is crucial, as they must maintain their effectiveness regardless of the elements they are exposed to. This article will explore how Cart Wheel Chocks hold up in different weather scenarios, from sunny days to the harshest storms.

The durability and reliability of Cart Wheel Chocks are tested in a multitude of weather conditions, including heat, cold, rain, snow, and ice. These chocks are designed to be robust and resilient, ensuring that they can withstand the wear and tear that comes with exposure to the elements. In high-temperature conditions, the materials used in the construction of Cart Wheel Chocks must be able to resist heat deformation, maintaining their structural integrity to keep vehicles securely in place. The same goes for cold weather, where the chocks must not become brittle or crack, which could compromise their effectiveness.

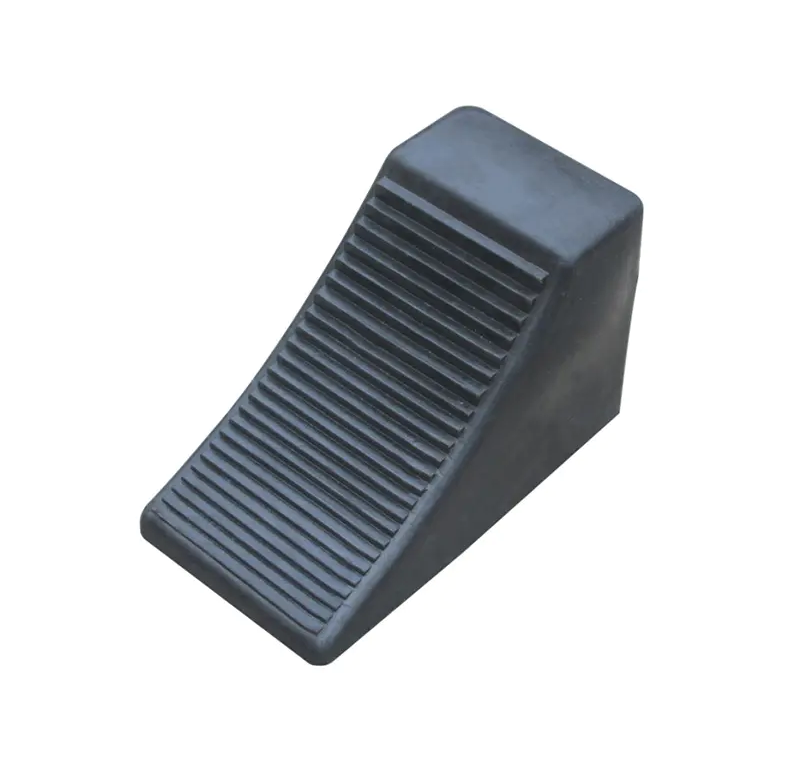

Rain is another factor that can affect the performance of Cart Wheel Chocks. Water can cause materials to swell or become slippery, which is why the design of these chocks includes features that prevent them from slipping on wet surfaces. The chocks must also be able to drain water effectively to avoid becoming waterlogged, which could reduce their stability. This is particularly important in areas prone to heavy rainfall or flooding.

Snow and ice present unique challenges for Cart Wheel Chocks. In snowy conditions, the chocks must be able to grip the ground firmly, even when it is covered in a layer of snow. This requires a design that can penetrate the snow and make contact with the ground beneath. In icy conditions, the chocks must not only maintain their grip but also resist the corrosive effects of salt, which is often used to de-ice roads and can damage metal components over time.

The performance of Cart Wheel Chocks in different weather conditions is not just about their physical resilience; it also involves their visibility. In low-light conditions or during foggy weather, the chocks must be easily visible to prevent accidents. This is why many chocks are manufactured in bright colors or with reflective materials that can be seen even in poor.

Another aspect to consider is the cleaning and maintenance of Cart Wheel Chocks after exposure to various weather conditions. The chocks should be easy to clean, with no crevices where dirt or debris can become trapped. This ensures that they remain in good condition and continue to perform effectively over time.

In conclusion, the performance of Cart Wheel Chocks in different weather conditions is a critical factor in their overall effectiveness as a safety device. They must be able to withstand heat, cold, rain, snow, and ice while maintaining their grip, visibility, and structural integrity. By understanding how these chocks perform in various weather conditions, we can better appreciate their importance in ensuring the safety of vehicles and the people around them. The adaptability of Cart Wheel Chocks to diverse weather conditions is a testament to their design and the materials used in their construction, making them a reliable choice for securing vehicles in any environment.