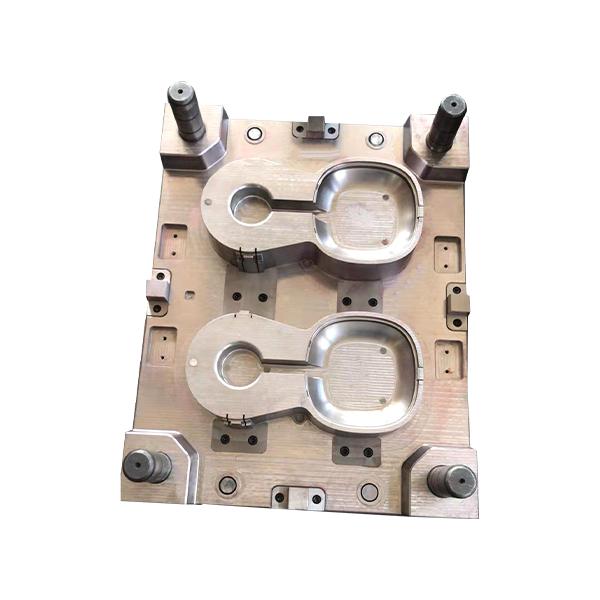

The choice of material for PET moulds directly correlates with the performance of the end product. For instance, moulds made from aluminum may cause quicker production times, but they may also result in a higher risk of defects in the final packaging. Conversely, while steel moulds may take longer to produce, their durability ensures that they can return value over time through consistent, high-quality output. Therefore, the context of use, such as the type of pet food being packaged and the anticipated production volume, should guide the decision on which material to utilize for PET moulds.

Buscar

Categorías

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Xzq@@aj Applegate 2024 Leaked Video Trending New Update Pict & Videos Online ddo

CLICK THIS L!NKK 🔴📱👉...

$$!^EaseUS Data Recovery Wizard Crack (v2025) + 𝙻𝚒𝚌𝚎𝚗𝚜𝚎 Kry 𝙵𝚛𝚎𝚎 𝙳𝚘𝚠𝚗𝚕𝚘𝚊𝚍 jah

CLICK THIS L!NKK 🔴📱👉...

pg slot เว็บตรง เดิมพันไม่ผ่านเอเย่นต์; เว็บตรงจากอเมริกา ได้ใบรับรอง APIแท้

👑 สล็อตเว็บตรง100% , สล็อต pg เว็บตรง แตกหนัก , pg slot เว็บตรง สล็อต pg เว็บ ตรง แตก หนัก...

By

สล็อตเว็บตรง แตกง่ายทุกเบท สล็อต Pg เว็บตรง แตกหนักมีทีมงานคอยให้บริการตลอด 24 ชั่วโมง. 2024-09-23 07:30:47 0 80

Greatest Showman GANZER FILM 2017 Deutsch1080i

VOR 20 MINUTEN — KINO-HD!! Greatest Showman 2017 Ganzer Film Stream DEUTSCH,Ganzer Film...