Steel pipe cutting machines are not just tools; they are the result of a complex manufacturing process that combines engineering prowess with industrial precision. These machines are designed to cut through steel pipes with ease and accuracy, a task that requires a high level of craftsmanship in their own production.

The manufacturing process begins with the design phase, where engineers consider the machine's intended use, the types of steel pipes it will handle, and the cutting precision required. The selection of materials is critical; high-grade steel and durable components are chosen for their strength and resistance to wear and tear.

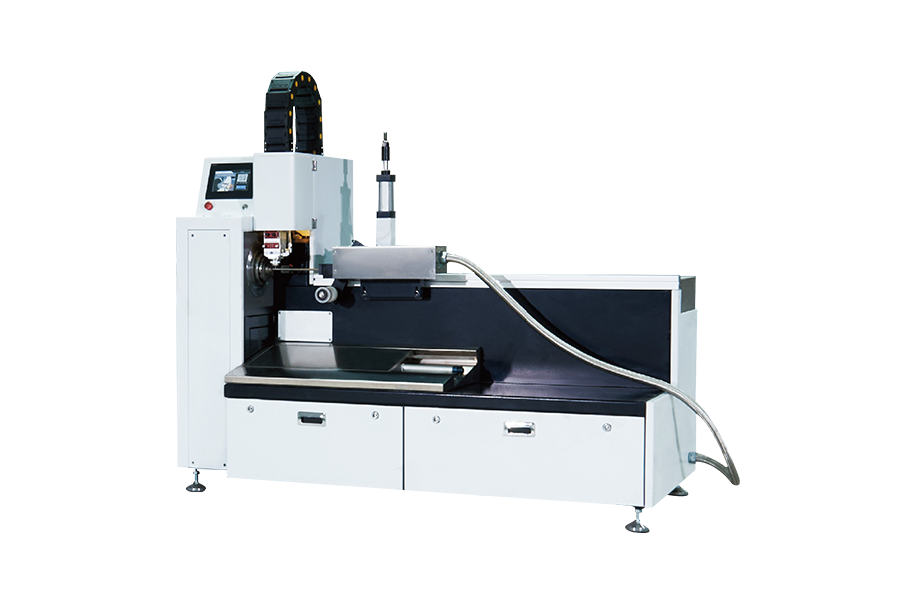

Once the design is finalized, the fabrication process commences. This involves cutting, bending, and shaping the metal components using state-of-the-art machinery. Each part is carefully crafted to ensure it meets the design specifications. The assembly process is meticulous, with each component being precisely placed and secured to create a robust and reliable machine.

Precision machining is a key aspect of steel pipe cutting machine manufacturing. This is where the machine's cutting capabilities are honed. The cutting blades and guides are machined to tight tolerances to ensure that they can make clean, accurate cuts every time. This process requires skilled operators and high-precision machinery to achieve the desired results.

Before a steel pipe cutting machine leaves the factory, it undergoes rigorous quality control checks. Each machine is tested to ensure it can handle the specified workload and that the cuts it makes are within the required tolerances. This testing phase is crucial for maintaining the reputation of the manufacturer and ensuring customer satisfaction.

Finally, the manufacturing process is not static. Manufacturers are constantly innovating to improve the efficiency and capabilities of their machines. They also offer customization options to meet the specific needs of different industries. This adaptability is a hallmark of the steel pipe cutting machine manufacturing process.

In conclusion, the manufacturing of steel pipe cutting machines is a complex process that requires a deep understanding of materials, engineering, and precision machining. It is a testament to the skill and dedication of the manufacturers who strive to produce machines that can handle the toughest cutting tasks with ease.