In the fast-paced world of laboratory research, efficiency and precision are paramount. For those utilizing microplate washers, such as the DIATEK Microplate Washer DRW-340, regular maintenance is critical to ensure optimal performance and longevity. This blog will explore the importance of maintaining your microplate washer and how it can enhance your laboratory operations.

1. Ensuring Consistent Performance

Reliability in Results

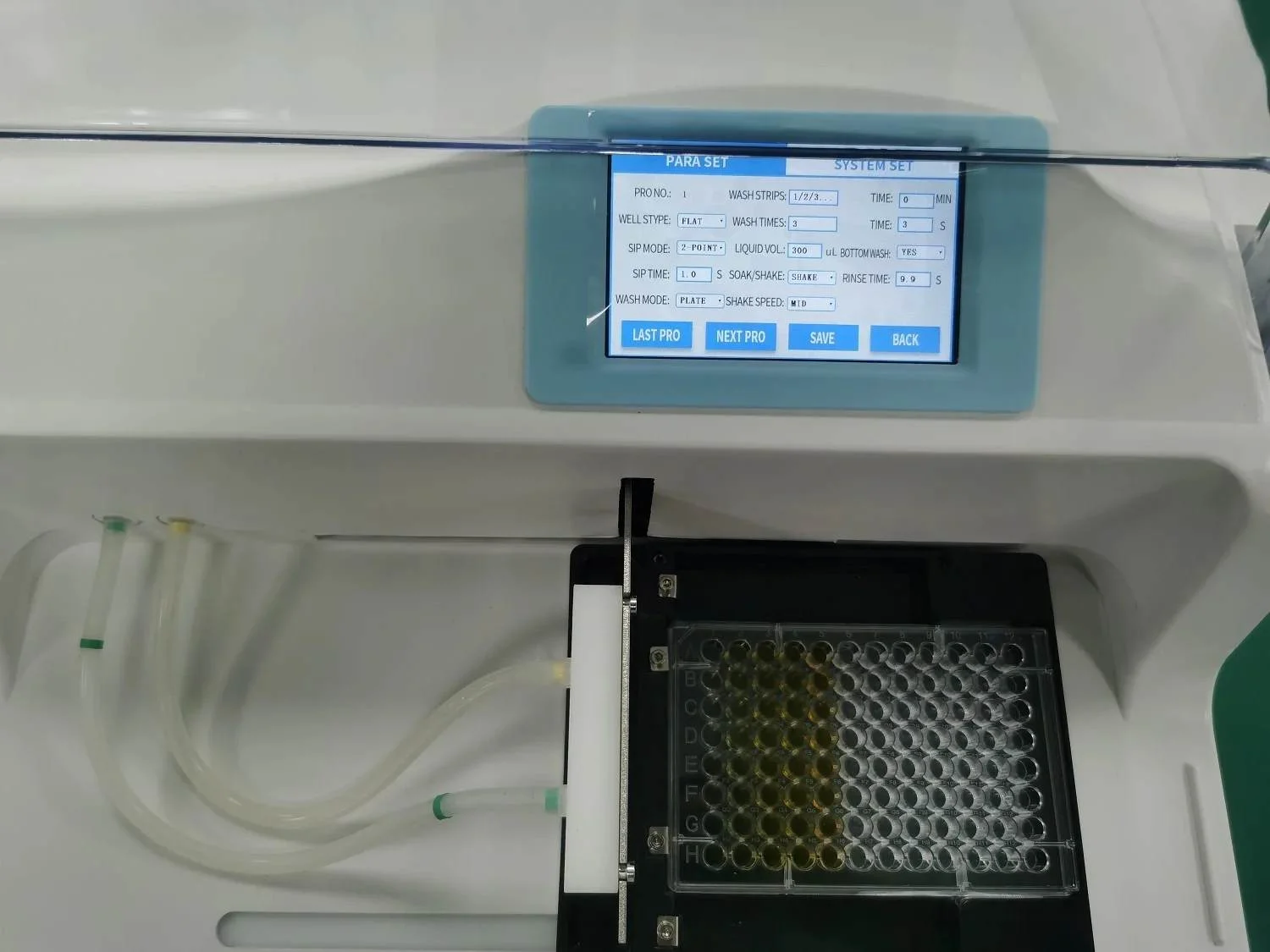

Regular maintenance of your microplate washer helps ensure consistent performance across all washing cycles. The DIATEK DRW-340 features customizable wash channels and a large capacitive touch screen, which can be affected by wear and tear if not properly maintained. By routinely checking and servicing the machine, you can avoid inconsistencies that may compromise your experimental results.

2. Preventing Equipment Malfunctions

Reducing Downtime

Microplate washers are intricate machines with multiple components that require regular attention. Neglecting maintenance can lead to equipment malfunctions, resulting in costly downtime. Regular checks on components like the Astin pump, pipettes, and manifold systems can help identify potential issues before they escalate into significant problems.

3. Enhancing Efficiency

Saving Time and Resources

A well-maintained microplate washer operates more efficiently, saving both time and resources. The DRW-340 is designed to minimize residual volume and optimize wash liquid usage during processing. Regular maintenance ensures that these features function correctly, allowing you to complete washing cycles more quickly and with less waste.

4. Improving Cleaning Efficacy

Achieving Optimal Results

The effectiveness of a microplate washer directly impacts the quality of your assays. Regular maintenance helps maintain the integrity of the wash process, ensuring complete bottom washes and effective liquid suction. By keeping the system clean and functional, you enhance the reliability of your experimental outcomes.

5. Extending Equipment Lifespan

Protecting Your Investment

Microplate washers represent a significant investment for any laboratory. Regular maintenance not only ensures optimal performance but also extends the lifespan of your equipment. By adhering to a maintenance schedule, you can avoid premature wear and tear on critical components, ultimately protecting your investment.

6. Ensuring Compliance with Standards

Meeting Regulatory Requirements

Many laboratories operate under strict regulatory standards that require routine maintenance of laboratory equipment. Keeping detailed records of maintenance activities for your microplate washer can help ensure compliance with these standards, reducing the risk of audits or inspections resulting in penalties.

7. Facilitating Safe Operation

Prioritizing User Safety

Regular maintenance checks help ensure that all safety features of your microplate washer are functioning correctly. The DIATEK DRW-340 includes features such as automatic rinsing of pipes after booting and adjustable soak times, which contribute to safe operation. Maintaining these systems reduces the risk of accidents or exposure to hazardous materials.

Conclusion

Regular maintenance for your microplate washer, like the DIATEK Microplate Washer DRW-340, is essential for ensuring consistent performance, preventing malfunctions, enhancing efficiency, improving cleaning efficacy, extending equipment lifespan, ensuring compliance with standards, and facilitating safe operation. By prioritizing maintenance, laboratories can achieve reliable results while maximizing their investment in equipment.

If you have any questions about maintaining your microplate washer or would like to learn more about our products, feel free to reach out! Let DIATEK support you in achieving excellence in your laboratory operations!